Pelletizing Plants

Danieli NewFer designs and delivers pelletizing plants based on travelling grate technology. Compared to other technologies on the market, travelling grate pelletizing plants have advantages of lower capital requirement, lower maintenance cost, higher availability and lower thermal energy consumption. Indurating furnaces with grate areas up to 786 m²—representing capacities up to 8 Mtpa—can be designed with project scopes ranging from test work and studies up to full engineering and supply packages including erection and commissioning support.

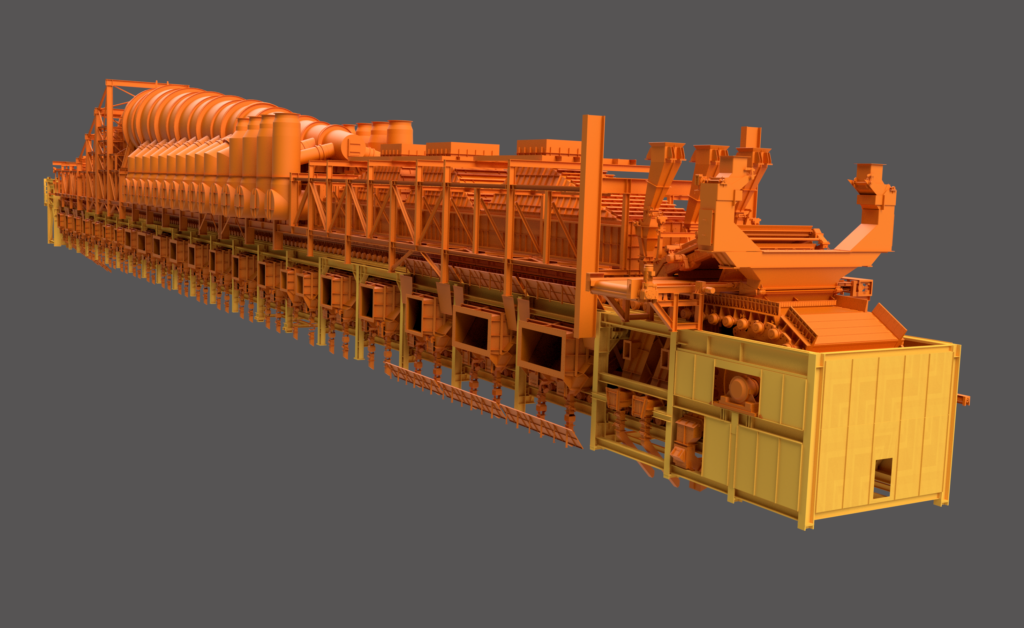

Travelling Grate

The pelletizing plants designed by Danieli NewFer are based on the travelling grate process. Plant arrangements are flexible with respect to fundamental design decisions related to e.g. green pelletizing processes (drum vs. disc), roller screens or gas cleaning technology. The travelling grate process itself has inherent advantages. It allows for larger capacities and higher availability along with higher flexibility with respect to the processed ores. Thermal energy consumption is lower and refractory wear is reduced. When applying travelling grate technology, pellet porosity and metallurgical properties are better compared to the results with alternative technology. Finally, CO2 emissions for the travelling grate process are the lowest of all available processes.

Heat Recovery

Thermal energy consumption is further reduced by the application of a specially developed heat recovery system based on so-called hot air cooling. This arrangement comes associated with a reduction in energy consumption for total energy cost that are up to 20% lower than with a standard design depending on the iron ore.

In terms of total operational cost, Danieli NewFer’s reference plant with a capacity of 4 Mtpa reference plant is currently achieving cost savings of approximately 6 million USD per annum using this solution.

Smart Automation and Advanced Process Control

The smart automation systems implemented by Danieli NewFer further improve overall plant efficiency. For example, pellet granulometry is monitored in real–time, helping achieve a lower standard deviation of the pellet size and enhanced pellet production through increased on–spec pellet machine feeding, to name but a few. Mixing of feed materials and binders is improved and indurating machine, heat distribution and gas flow are optimized for more efficient pellet induration.

For more information on these systems, please refer to our DigiFer® Process Automation line of products.

Lower energy consumption

20 %

References

14

Added capacity

50 mtpa

Added grate area

> 5800 m²

We have completed pelletizing projects on all continents and with scope ranging from test work and packages such as burner supplies and automation systems all the way up to complete, greenfield pelletizing plants. Our people have a wide variety of backgrounds and are used to working in all cultures and environments. With industrial experience of up to 30 years, we confidently state that we offer true excellence in travelling grate pelletizing technology.