Iron Ore Beneficiation: turning low–grade ores into high–value feed

At Danieli Newfer, we deliver integrated engineering solutions for iron ore beneficiation—combining advanced process design, precision equipment engineering, and on-site technical expertise. Our support extends from concept development to full operational readiness, ensuring that every plant achieves stable, efficient, and predictable performance.

Engineering & Design

We provide fully integrated engineering and process design for both dry- and wet-beneficiation. Our work is tailored to the mineralogy, liberation characteristics, particle size distribution, and operating context of each ore body.

What we deliver

- Flowsheet development validated by test work and simulation

- Mass balance and equipment sizing with design criteria

- PFDs, P&IDs, control philosophies, and interlock strategies

- Mechanical and layout engineering, maintainability, and access provisions

- Integrated crushing, grinding, classification, gravity, and magnetic separation systems

- Constructible engineering packages supporting efficient construction, commissioning, and ramp-up

Outcome: Stable, efficient, and predictable plant performance, with reduced rework and faster time‑to‑nameplate.

Audits & Optimisation

Our fact–finding audits establish a true picture of current performance and loss drivers. We combine historical data, targeted sampling campaigns, on–site measurements, and USIM PAC models to diagnose constraints and quantify recovery opportunities.

Focus areas

- Bottleneck analysis and rate-limiting stages

- Classification performance (partition curves, recirculating loads)

- Magnetic circuit efficiency (field intensity, matrix/filling, feed density)

- HPGR utilisation (specific throughput, pressure, PSD control)

- Gravity circuits (yield distribution, cut densities, water balance)

- Energy, water, and mass balance reconciliation and variance analysis

Outcome: A clear, prioritised improvement roadmap with quantified benefits and implementation steps.

Process Enhancement & Fine–Tuning

Post‑audit, we implement targeted optimisation using real-time data evaluation, mPost‑audit, we implement targeted optimisation using real-time data evaluation, model-based setpoint definition, and structured plant trials.

Typical optimisation levers

- Classifier/cyclone cut point and pressure control

- Screens/air classifiers: efficiency, blinding control, bypass reduction

- Magnetic separation: field intensity, matrix configuration, feed density/flow regime

- HPGR: pressure setpoint, edge recycling, roll skew, feed presentation, specific energy

- Gravity circuits: splitters, density setpoints, stage mass pulls

- Dewatering/filtration: thickener underflow density, floc dosing, vacuum/pressure filters

Outcome: Higher throughput, tighter product grade bands, improved recovery, and reduced specific energy and water consumption—without compromising stability.

Research & Test Work

Every beneficiation solution begins with a deep understanding of the ore. To ensure reliable plant design and predictable performance, we conduct bench-scale and pilot-scale test work in cooperation with accredited, globally recognised laboratories.

This collaborative model gives our clients access to world-class facilities and specialised mineral testing capabilities—without the limitations of a fixed laboratory footprint. Through these partnerships, we generate high-quality data that forms the foundation of our basic engineering, flowsheet selection, and process guarantees.

Benefits: Confident grade–recovery predictions, optimised flowsheet selection, lower project and operational risk, and clear guidance for both greenfield and brownfield projects.

Process Simulation & Modelling (USIM PAC)

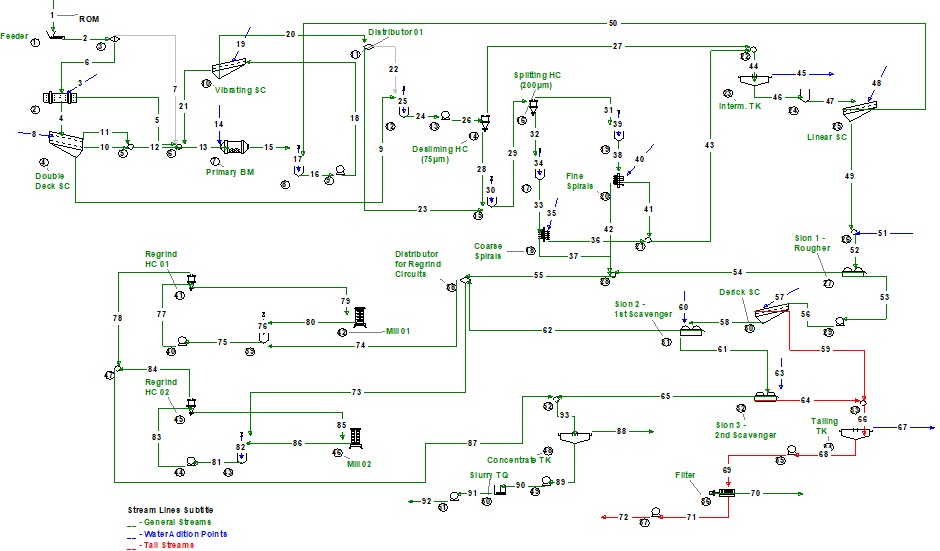

To design accurate and predictable beneficiation plants, we use USIM PAC, one of the inTo design accurate and predictable beneficiation plants, we use USIM PAC, one of the industry’s leading process simulation platforms. Through detailed modelling of crushing, grinding, classification, gravity circuits, magnetic separation, and dry/wet beneficiation routes, we are able to:

- Evaluate and compare alternative flowsheets

- Predict grade, recovery, and throughput under different operating conditions

- Optimise recirculating loads, cut‑points, and energy consumption

- Identify bottlenecks before investment decisions

- Validate design parameters using lab and pilot test data

Simulation results form an essential part of our basic engineering, ensuring that every recommended flowsheet is backed by robust technical justification.

Project Delivery

We execute through gated phases to control risk and ensure traceable quality.

- Concept & Options: Ore characterisation, trade‑off studies, show‑stoppers

- Pre‑FEED/Basic Engineering: Basis of Design, flowsheets, mass balance, equipment lists, layouts

- Detailed Engineering: Discipline drawings, vendor integration, control logic, HAZOP readiness

- Procurement & Fabrication Support: Technical evaluations, inspections, expediting

- Construction & Commissioning: Installation support, loop checks, dry/wet commissioning, ramp‑up plans

- Performance Guarantee Support: Test protocols, measured KPIs, defect punch‑lists, optimisation plan

References

6

Plant capacity

4 Mtpa