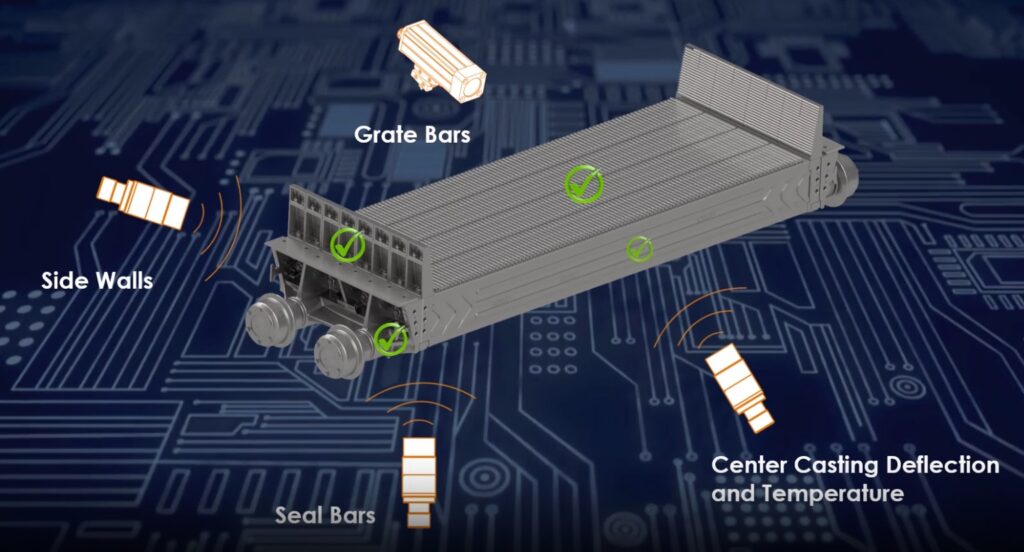

DigiFer® Track Pallet Car and Grate Monitoring System

DigiFer® Track is an automation and digitalization solution designed for real-time monitoring of pallet cars and grate components in indurating machines.

The system enhances equipment reliability and supports predictive maintenance by detecting mechanical and thermal anomalies at an early stage.

Main Features

The DigiFer Track® system provides continuous, real-time monitoring of critical pallet car and grate components in indurating machines, supporting early fault detection and predictive maintenance strategies. Key features include:

- OPC-UA communication, providing seamless interface with Level I and Level II automation systems

- Grate bar gap monitoring, enabling early detection of misalignments and abnormal openings

- Seal bar mechanism monitoring, including gap measurement between seal bar and slide track to identify wear or mechanical deviation

- Side wall condition monitoring, supporting early detection of structural degradation

- Center casting deflection monitoring, allowing identification of abnormal mechanical stress and deformation trends

- Temperature monitoring of critical components, enabling early detection of overheating and thermal anomalies

- Image- and sensor-based diagnostics, designed for reliable operation under harsh industrial conditions

Expandability and Feature Development

Additional monitoring features and diagnostic functions can be progressively introduced based on plant-specific maintenance strategies and operational priorities.